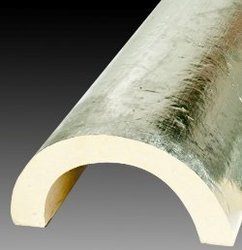

Polyurethane Foam Pipe Section

Polyurethane Foam Pipe Section Specification

- Coating Type

- Aluminium foil/ Kraft/ PVC coating available

- Feature

- High thermal resistance, low water absorption, lightweight, easy to install

- Thermal Conductivity

- 0.022-0.025 W/mK

- Installation Guideline

- Sections should be fitted tightly over pipes, and joints sealed with matching adhesive or tape; follow standard insulation practices.

- Layer

- Single or Multiple Layer

- Density

- 45 Gram per cubic centimeter(g/cm3)

- Surface Treatment

- Can be laminated with aluminium foil, kraft paper, or PVC jacket

- Size

- Standard and custom sizes available as per pipe diameter

- Product Type

- Pipe Section

- Material

- Polyurethane Foam

- Tensile Strength

- 120 kPa

- Width

- Customizable as per Pipe OD

- Thickness

- 25 mm, 40 mm, 50 mm, 75 mm, 100 mm

- Application

- Thermal insulation of pipelines for HVAC, chilled water, refrigeration, chemical plants, oil & gas industries

- Heat Conductivity

- 0.022-0.025 W/mK

- Color

- Yellow

- Max Withstanding Temperature

- Up to 120C

Polyurethane Foam Pipe Section Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Polyurethane Foam Pipe Section

To meet the diverse requirements of our valued patrons, we are engrossed in offering high grade Polyurethane Foam Pipe Section. Installed in hotels, offices, malls, shopping complexes and other places, this section is known for its water & shrink resistance. Using quality assured polyurethane foam, the provided section is fabricated and designed by ingenious professionals at our modern premises. In addition, this Polyurethane Foam Pipe Section is ideal to be fixed to various type of pipes.

Key features:

- Good dimensional and thermal insulation property with high compressive strength

- Uniform density

- Fine finish

- Comes in varied specifications to suits clients need

Specifications:

- Thickness:25mm and above

- Length:1000mm

- Superior Insulating Efficiency Leading To Energy Savings

- Void Free Insulation

- Durable

- Water And Moisture Resistant

- Dimensionally Stable

- Resistant To Most Oils, Chemicals, And Solvents

- No Thermal Bridges

Superior Insulation for Demanding Applications

Designed for both standard and bespoke pipeline sizes, these pipe sections excel in thermal resistance and mechanical strength, making them ideal for demanding environments found in HVAC, refrigeration, chemical, and oil & gas systems. Their closed-cell structure minimizes water ingress and maintains peak insulation performance over time.

Fire Safety and Environmental Assurance

Our product is formulated to restrict flame propagation, achieving a self-extinguishing rating as per IS 12436. With zero formaldehyde, and being completely CFC/HCFC-free, it meets strict environmental standards, ensuring a safer, greener solution for industrial and commercial insulation needs.

Customizable Finishes and Simple Installation

Choose from aluminium foil, kraft paper, or PVC jacketing to boost UV resistance and mechanical protection. Each section is lightweight and engineered for straightforward installationsimply secure tightly to the pipe, seal joints with approved adhesive or tape, and follow standard insulation practices for optimal results.

FAQs of Polyurethane Foam Pipe Section:

Q: How is polyurethane foam pipe section installed on pipelines?

A: Installation involves fitting the foam sections snugly over the cleaned pipe surface. Ensure that joints are sealed with matching adhesive or insulation tape, and use recommended techniques to minimize thermal bridging. Detailed installation guidelines should be followed for best thermal performance.Q: What thickness options are available and how do I select the right one for my application?

A: Thicknesses range from 25 mm to 100 mm. The appropriate thickness depends on factors like pipe diameter, operating temperature, and required thermal insulation level. Consult industry standards or our technical team for guidance specific to your system requirements.Q: When should protective coatings be considered for these pipe sections?

A: Protective coatings such as aluminium foil, kraft paper, or PVC jackets are recommended for pipes exposed to UV radiation, outdoor elements, or mechanical wear. This enhances durability and UV resistance, prolonging insulation life in challenging environments.Q: Where can these foam pipe sections be used?

A: They are suitable for HVAC systems, chilled water and refrigeration lines, chemical processing plants, and oil & gas pipelines. Their high thermal resistance and low water absorption make them versatile for both indoor and outdoor industrial settings.Q: What is the benefit of the closed-cell structure in these pipe sections?

A: Over 90% closed-cell content means the foam resists water absorption and vapor permeation, retaining thermal performance and preventing deterioration over time, even in humid or wet conditions.Q: How does this product comply with environmental and fire safety standards?

A: It is self-extinguishing as per IS 12436, and contains no CFCs, HCFCs, or formaldehyde, ensuring it meets both fire safety and environmental protection standards. Its eco-friendly formulation makes it suitable for sustainable projects.Q: What is the process for ordering custom sizes or diameters?

A: You can specify your required pipe diameter, section length, width, and thickness. Our manufacturing and exporting team based in India will tailor-make your order, providing custom solutions for standard or non-standard piping configurations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Pipe Section Category

PU Pipe Sections

Minimum Order Quantity : As per order , , Piece

Tensile Strength : 0.20.3 MPa

Density : 40 Gram per cubic centimeter(g/cm3)

Color : Yellow (Standard)

Surface Treatment : Plain or Jacketing (Aluminum/HDPE) Available

Thickness : 30 mm to 150 mm

PUF Pipes Section

Minimum Order Quantity : As per order , , Piece

Tensile Strength : 0.21 N/mm

Density : 40 Gram per cubic centimeter(g/cm3)

Color : Yellow

Surface Treatment : Cladded with Aluminum/SS/GI Sheet or as per requirement

Thickness : 20 mm to 100 mm

Pipe Section

Minimum Order Quantity : As per order Piece

Tensile Strength : 0.20 0.30 N/mm

Density : 40 Gram per cubic centimeter(g/cm3)

Color : Yellow / Cream

Surface Treatment : Plain, Aluminum foil, or Kraft faced

Thickness : 25 mm to 100 mm

PIR Pipe Sections

Minimum Order Quantity : As per order Piece

Tensile Strength : 200 kPa

Density : 42 Gram per cubic centimeter(g/cm3)

Color : Yellow/Offwhite

Surface Treatment : Smooth or with aluminum foil/laminate jacket

Thickness : 25 mm, 40 mm, 50 mm, 75 mm, 100 mm (custom available)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free