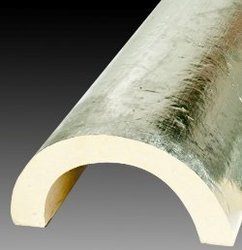

PUF Pipes Section

PUF Pipes Section Specification

- Installation Guideline

- Directly fitted and sealed on pipes, ensure tight joints for best performance

- Layer

- Single or multi-layered as per insulation thickness required

- Coating Type

- Optional Aluminum, SS, GI, or other claddings

- Thermal Conductivity

- 0.022 W/mK

- Density

- 40 Gram per cubic centimeter(g/cm3)

- Surface Treatment

- Cladded with Aluminum/SS/GI Sheet or as per requirement

- Size

- Available from 0.5 inch to 16 inch NB, custom sizes on request

- Feature

- Closed cell structure, high insulation efficiency, lightweight

- Product Type

- Insulation Pipe Section

- Material

- Polyurethane Foam (PUF)

- Tensile Strength

- 0.21 N/mm

- Width

- Customized as per pipe diameter

- Thickness

- 20 mm to 100 mm

- Application

- Thermal insulation for industrial and commercial piping systems

- Heat Conductivity

- 0.022 W/mK

- Color

- Yellow

- Max Withstanding Temperature

- -200C to +110C

- Service Life

- 15+ years under normal operating conditions

- Water Absorption

- < 2% by volume

- Pipe Diameter Range

- 15 mm to 500 mm

- Fire Resistance

- Self-extinguishing PUF core; conforms to fire safety standards

- Dimensional Stability

- Excellent; maintains shape over time

- Cladding Thickness

- 0.5 mm to 1 mm

- Compressive Strength

- > 2.0 kg/cm

- Closed Cell Content

- >90%

- Customization

- Available in pre-formed sections for elbows, bends, reducers and tees

- Eco-Friendliness

- CFC free, environmentally friendly

PUF Pipes Section Trade Information

- Supply Ability

- 01 , , Piece Per Month

- Delivery Time

- 1-4 Week

About PUF Pipes Section

PRODUCT DESCRIPTION:

- Rigid PU foam cored Pipe sections manufactured and available in standard sizes have excellent thermal insulation properties and make a valuable contribution towards reducing energy consumption in various industries. PU foam cored Insulated Pipe Sections are manufactured with the help of a dedicated High Pressure equipment using state of art moulds and fixtures to consistently yield:

- Environment friendly CFC-free Polyurethane Foam of desired and uniform density

- Close cell content of over 90%

- Excellent dimensional & thermal insulation properties together with compressive strength this added dimension makes it a tit construction material OPIPL offers a wide range of READY TO APPLY Polyurethane foam core Insulated Pipe Section

FEATURES / ADVANTAGES :

- Superior insulating efficiency leading to energy savings.

- Void free insulation

- Durable

- Water and moisture resistant

- Dimensionally stable

- Resistant to most oils , chemicals , and solvents

- No thermal bridges

- Fire resistant

AVAILABLE IN PUR AND PIR

DETAILS OF PUF PIPE SECTION

- Pipe Size To 24

- Thickness- 25mm And Above.

- Length- 1000mm

- Density 36kg/M3 And Above.

For thickness above 100mm we offer pipe sections in double or triple layers as per customers requirement.

For Pipe Size over 24 we recommend Puf Sheets for Pipe Line insulation.

Superior Fire Safety and Thermal Insulation

Our PUF Pipe Sections are engineered to offer both top-tier heat insulation and uncompromising fire safety. The self-extinguishing, closed-cell PUF core adheres to rigorous fire safety standards, protecting infrastructure and personnel. With ultra-low thermal conductivity (0.022 W/mK), these pipe sections ensure impressive energy conservation in diverse climates and operational settings.

Long-Lasting, Eco-Friendly Construction

Designed for a service life exceeding 15 years, the PUF Pipe Sections retain their shape and insulation properties over time thanks to premium material selection and dimensional stability. They are CFC-free and friendly to the environment, making them a responsible choice for energy-efficient projects. Customization options further support specialized industrial applications.

FAQs of PUF Pipes Section:

Q: How do PUF Pipe Sections enhance fire safety in piping systems?

A: PUF Pipe Sections are constructed with a self-extinguishing PUF core that conforms to fire safety standards. This fire resistance feature ensures that, in the event of a flame, the material suppresses the spread, providing vital protection to assets and personnel.Q: What benefits do PUF Pipe Sections offer in terms of moisture resistance?

A: With a closed-cell content greater than 90% and water absorption less than 2% by volume, these sections prevent moisture ingress, preserving insulation performance and minimizing the risk of corrosion under insulation.Q: When should PUF Pipe Sections be used for piping insulation?

A: PUF Pipe Sections are ideal for insulating industrial and commercial piping where thermal efficiency, fire safety, and durability are essential, especially in temperature ranges between -200C and +110C.Q: Where are these PUF Pipe Sections commonly installed?

A: These sections are widely used across power plants, chemical factories, oil refineries, refrigeration plants, and commercial buildings wherever high-performance pipe insulation is required.Q: What is the installation process for PUF Pipe Sections?

A: Installation involves directly fitting the pre-formed sections onto pipes and sealing all joints tightly to ensure optimal insulation. Proper cladding is applied as needed for additional protection.Q: How do customized PUF Pipe Sections support different piping system designs?

A: Customization is available for elbows, bends, tees, and reducers, allowing seamless insulation for complex piping geometries and ensuring continuous thermal protection throughout the piping network.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Pipe Section Category

PIR Pipe Sections

Minimum Order Quantity : As per order Piece

Size : Customized as per pipe diameter and length (typically 1 m length per section)

Surface Treatment : Smooth or with aluminum foil/laminate jacket

Material : Polyisocyanurate (PIR) Rigid Foam

Application : Thermal insulation of HVAC, refrigeration, chilled water, and process piping

Tensile Strength : 200 kPa

Pipe Section

Minimum Order Quantity : As per order Piece

Size : Pipe diameter 1/2 to 24 and above

Surface Treatment : Plain, Aluminum foil, or Kraft faced

Material : Rigid Polyurethane Foam (PUF)

Application : Thermal insulation of pipelines for chillers, HVAC, process industries, and refrigeration systems

Tensile Strength : 0.20 0.30 N/mm

Polyurethane Foam Pipe Section

Minimum Order Quantity : As per order Piece

Size : Standard and custom sizes available as per pipe diameter

Surface Treatment : Can be laminated with aluminium foil, kraft paper, or PVC jacket

Material : Polyurethane Foam

Application : Thermal insulation of pipelines for HVAC, chilled water, refrigeration, chemical plants, oil & gas industries

Tensile Strength : 120 kPa

Polyurethane Pipe Section

Minimum Order Quantity : As per order Piece

Size : For pipe outer diameter inch to 24 inch (or customized sizes)

Surface Treatment : Plain Mat Finish

Material : Polyurethane (PU) Foam

Application : Thermal insulation for hot and cold pipelines in HVAC, process industries, oil & gas, chemical plants, refrigeration

Tensile Strength : 0.150.30 MPa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS