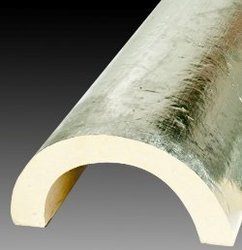

Pipe Section

Pipe Section Specification

- Layer

- Single or multi-layer as required

- Installation Guideline

- Fit tightly around pipe, secure with recommended adhesive and/or covering

- Size

- Pipe diameter 1/2 to 24 and above

- Density

- 40 Gram per cubic centimeter(g/cm3)

- Feature

- High insulation value, lightweight, moisture resistant, fire retardant

- Thermal Conductivity

- 0.022 0.028 W/mK

- Coating Type

- Optional: Aluminum foil or Kraft paper

- Surface Treatment

- Plain, Aluminum foil, or Kraft faced

- Product Type

- Preformed Pipe Section

- Material

- Rigid Polyurethane Foam (PUF)

- Tensile Strength

- 0.20 0.30 N/mm

- Width

- Customizable as per requirement

- Thickness

- 25 mm to 100 mm

- Application

- Thermal insulation of pipelines for chillers, HVAC, process industries, and refrigeration systems

- Heat Conductivity

- 0.022 0.028 W/mK

- Color

- Yellow / Cream

- Max Withstanding Temperature

- up to 110C

- Shape

- Cylindrical/preformed half shells

- Water Absorption

- <2% by volume

- Compressive Strength

- 0.15 kg/cm at 10% deformation

- Suitable Environment

- Indoor & outdoor insulation with weather protection cladding

- Standard Conformity

- IS 12436 / ASTM C 1029

- Fire Class

- Self extinguishing, Class O/1 possible

- Pipe Compatibility

- Steel, copper, PVC, HDPE, and other industrial pipes

- Closed Cell Content

- >90%

- Service Life

- 1520 years under normal conditions

Pipe Section Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Pipe Section

Established in the year 1994, we are a renowned entity engaged in providing premium grade Pipe Section. Known for easy fitting, the provided section is best suited for piping purpose. The offered section is manufactured using top notch quality raw materials at our premises. The offered Pipe Section is suitable for the insulation of small and large diameter heating and ventilation pipes.

Features:

- High strength

- Quick installation

- Strong design

- Fine finish

- Thickness:25mm and above

- Length:1000mm

Other Details:

- Superior Insulating Efficiency Leading To Energy Savings

- Void Free Insulation

- Durable

- Water And Moisture Resistant

- Dimensionally Stable

- Resistant To Most Oils, Chemicals, And Solvents

- No Thermal Bridges

- Fire Resistant

Superior Insulation Performance

Manufactured using rigid PUF with high closed-cell content, these pipe sections deliver excellent thermal conductivity (0.0220.028 W/mK), ensuring consistent insulation for both indoor and outdoor applications. Their moisture resistance and fire-retardant properties enhance system safety and efficiency over a service life of 1520 years.

Easy Customization and Installation

Available in various thicknesses (25100 mm) and customizable widths, our pipe sections fit a broad range of pipe diameters. Surface treatments such as plain, aluminum foil, or Kraft paper boost protective qualities. Installation is straightforward: simply fit tightly around the pipe, securing with adhesive and optional weather-protective coverings.

Versatility in Application

Suited for both industrial and commercial environments, these pipe sections insulate steel, copper, PVC, HDPE, and other industrial pipelines. Ideal for thermal insulation in HVAC, refrigeration, chilled water, and process industry systems, they maintain low heat loss even under demanding conditions.

FAQs of Pipe Section:

Q: How are these pipe sections installed for optimal insulation?

A: To ensure maximum performance, each section should be securely fitted around the pipe and joined using the recommended adhesive. For outdoor applications, protective cladding such as aluminum foil or Kraft paper is advised for additional weatherproofing.Q: What benefits do rigid PUF pipe sections provide for pipeline insulation?

A: These pipe sections offer high thermal resistance, moisture resistance, and fire retardancy. Their structure minimizes heat loss, extends the lifespan of pipelines, and helps conserve energy in HVAC, industrial, and refrigeration systems.Q: When should aluminum foil or Kraft paper coatings be used?

A: Aluminum foil or Kraft coatings are recommended when extra protection against moisture, mechanical impact, or weather exposure is required, especially in outdoor or harsh environments.Q: Where can these pipe sections be applied?

A: They are suitable for both indoor and outdoor pipeline insulation across chillers, HVAC systems, refrigeration lines, and various process industries. With proper cladding, they withstand diverse environmental conditions.Q: What is the process for customizing pipe section sizes?

A: Pipe sections can be tailored for different diameters (from 1/2 inch to 24 inches and above) and thicknesses (25100 mm). Provide your specific requirements to the supplier for precision manufacturing.Q: Which types of pipes are suitable for these PUF sections?

A: These pipe sections are compatible with steel, copper, PVC, HDPE, and other industrial pipelines, making them a universal solution for pipeline insulation needs.Q: What fire safety standards do these pipe sections meet?

A: They are self-extinguishing and can meet Class O or Class 1 fire ratings, ensuring adherence to safety regulations and enhancing protection in case of fire exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Pipe Section Category

Polyurethane Pipe Section

Minimum Order Quantity : As per order Piece

Size : For pipe outer diameter inch to 24 inch (or customized sizes)

Installation Guideline : Can be easily cut and installed directly on pipes; use adhesive and proper vapor barrier; secure with aluminum or GI cladding for outdoor use

Heat Conductivity : 0.0200.024 W/mK

Width : Varies as per pipe diameter

Thermal Conductivity : 0.0200.024 W/mK

PU Pipe Sections

Minimum Order Quantity : As per order , , Piece

Size : Customized as per pipe diameter

Installation Guideline : Can be applied directly over pipes; joint sealing with adhesive or tape recommended

Heat Conductivity : 0.022 0.024 W/mK

Width : As per requirement (Typically 1 meter)

Thermal Conductivity : 0.022 0.024 W/mK

Polyurethane Foam Pipe Section

Minimum Order Quantity : As per order Piece

Size : Standard and custom sizes available as per pipe diameter

Installation Guideline : Sections should be fitted tightly over pipes, and joints sealed with matching adhesive or tape; follow standard insulation practices.

Heat Conductivity : 0.0220.025 W/mK

Width : Customizable as per Pipe OD

Thermal Conductivity : 0.0220.025 W/mK

PIR Pipe Sections

Minimum Order Quantity : As per order Piece

Size : Customized as per pipe diameter and length (typically 1 m length per section)

Installation Guideline : Install on clean, dry pipes with minimal gaps; joints to be properly sealed

Heat Conductivity : 0.0210.024 W/mK

Width : From DN 15 mm up to DN 400 mm

Thermal Conductivity : 0.0210.024 W/mK

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free