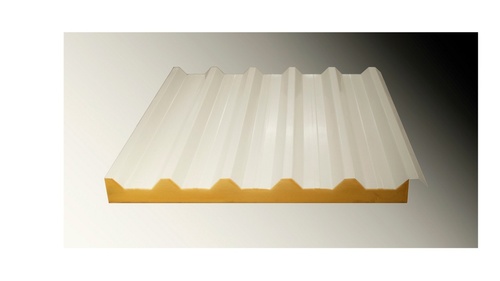

Roofing Puf Sandwich Panel

Roofing Puf Sandwich Panel Specification

- Application

- Warehouses, Cold Storages, Industrial Sheds, Commercial Buildings

- Features

- Fire Resistant, Thermal Insulation, Acoustic Insulation, Leak Proof

- Color

- Blue, White, Green, Grey, as per requirement

- Material Grade

- IS: 14246 / ASTM A653 (GI Sheet); CFC Free PUF Core

- Form

- Sandwich Panel Sheets

- Load Capacity

- High Load Bearing, suitable for snow and wind loads

- Machines Type

- Roof Panel Roll Forming Machine

- Thickness

- 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm (customizable)

- Installation Type

- Interlocking / Overlapping Joint System

- Usage

- Industrial/Commercial/Residential Roofing

- Product Type

- Roofing Puf Sandwich Panel

- Size

- Length: Customized (up to 12 meters); Width: Standard 1000 mm

- Feature

- High Insulation, Weather Resistance, Light Weight

- Shape

- Trapezoidal

Roofing Puf Sandwich Panel Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Roofing Puf Sandwich Panel

Reckoned for quality and honest business practices, we are engaged in manufacturing and supplying optimum quality Roofing Puf Sadwich Panel. Our skilled professionals manufacture these panels using the best grade basic materials in order to ensure their flawlessness. To cater to different requirements of industries, we offer this Roofing Puf Sadwich Panel in different facing such as GI pre-coated, SS, bituminous paper, aluminum foil paper, kraft paper and many more.

Key Features:

- Anti-corrosive

- Low maintenance

- Durable standards

- Optimum functionality

Other Details:

Product Details-

- Length - Up to 6mtr.

- Width - Up to 1.2mtr

- Thickness- 25mm to 150mm.

- Note- 25mm to 40mm thickness available up to certain length.

- Tongue and Groove with specially designed CAM LOCKS.

- Density - 40kg/m3

Facing

- Ply

- FRP Sheets.

- Aluminium etc.

- Gi Pre Coated

- SS

- Bituminous Paper

- Aluminium Foil Paper

- Kraft Paper

- Ply

- F Sheets.

- Aluminium Etc.

ADVANTAGES / BENEFITS

- Thin Walls

- Optimum Insulation Without Thermal Bridges

- Components Can Be Disassembled And Reused

- Outstanding Load Bearing Capacity

- Hygenic For Food Preservation

- Odorless

- Long Life And Durable

- Resistant To Most Oils , Chemicals And Solvents

- Fire Resistant.

Exceptional Thermal and Acoustic Insulation

With a panel density of 402 kg/m and advanced PUF core, these roofing panels offer thermal conductivity of 0.022 W/mK, keeping interiors cool and energy-efficient. The structure also provides sound insulation up to 25 dB, making them ideal for locations requiring reduced noise, such as warehouses and commercial facilities.

Customizable Design for Varied Applications

The panels come in thicknesses from 30 mm to 100 mm, with metal sheets customizable between 0.4 mm and 0.6 mm. Choose from finishes (glossy or matte), colors (blue, white, green, grey), and joint types (tongue & groove or overlap) to suit architectural and environmental needs. Lengths can be specified up to 12 meters.

Robust Weather and Fire Resistance

Designed to withstand heavy snow, wind loads, and harsh weather, the panels offer high UV stability and water absorption rates below 2%. Manufactured from GI sheets (IS: 14246 / ASTM A653) and CFC-free PUF core, the panels are also fire-resistant, making them a safe roofing solution. Rain-protected packaging ensures damage-free delivery.

FAQs of Roofing Puf Sandwich Panel:

Q: How do Roofing Puf Sandwich Panels provide superior insulation for buildings?

A: These panels feature a high-density PUF core (402 kg/m) with excellent thermal conductivity (0.022 W/mK), effectively minimizing heat transfer and keeping interiors comfortable throughout the year.Q: What installation process is recommended for these sandwich panels?

A: Installation utilizes an interlocking or overlapping joint system, including tongue & groove or overlap joints. This method ensures a leak-proof roof and enhances structural stability for industrial, commercial, or residential buildings.Q: When should I choose different panel thicknesses for my roofing application?

A: Panel thickness can be selected based on insulation requirements, structural load, and climate conditions. Thicker panels (up to 100 mm) are ideal for cold storage or extreme climates, while thinner ones suit less demanding environments.Q: Where are Roofing Puf Sandwich Panels most commonly used?

A: These panels are widely used in warehouses, cold storages, industrial sheds, and commercial buildings due to their weather resistance, thermal and acoustic insulation, and robust fire safety features.Q: What benefits do the joint types and finishing options offer?

A: Tongue & groove and overlap joints provide superior leak-proofing and ease of installation, while glossy or matte finishes enhance UV stability, aesthetics, and durability in varied environmental conditions.Q: How does the water absorption rate impact panel performance?

A: With water absorption below 2% by volume, the panels resist moisture infiltration, contributing to longer life, reduced maintenance, and strong weatherproofing for exposed roofing applications.Q: What makes these panels suitable for export and supply across India?

A: Conforming to IS: 14246 / ASTM A653 standards, high load-bearing capacity, and protective stacking on wooden pallets ensure quality and reliability for shipping, making them a preferred choice for exporters and suppliers nationwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Sandwich Panel Category

Ahu Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Product Type : Ahu Puf Sandwich Panel

Usage : Air Handling Units, HVAC Ducting, Pharmaceutical Cleanrooms

Installation Type : Modular, Prefabricated Assembly

Thickness : 30 mm, 40 mm, 50 mm, 60 mm, up to 150 mm

Load Capacity : High Structural Strength for HVAC Applications

Cold Storage Puf Sandwich Panel

Minimum Order Quantity : As per order , , Piece

Product Type : Cold Storage Puf Sandwich Panel

Usage : Cold Rooms, Ripening Chambers, Fruit and Vegetable Storage

Installation Type : Tongue and Groove Joint with Cam Lock System

Thickness : 40mm, 50mm, 60mm, 80mm, 100mm, 120mm, 150mm, 200mm (Various as per requirement)

Load Capacity : Designed as per Structure Requirement

Room Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Product Type : Room Puf Sandwich Panel

Usage : Thermal and acoustic insulation

Installation Type : Interlocking tongue and groove or cam lock system

Thickness : 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm (as required)

Load Capacity : Varies with thickness & design; up to 150 kg/m

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS