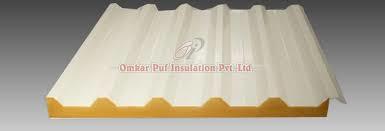

Puf Roofing Panel

Puf Roofing Panel Specification

- Usage

- Prefabricated roofing, insulation for cold storage, industrial and commercial buildings

- Machines Type

- Panel Forming Machine

- Color

- Available in multiple colors (red, blue, green, white, etc.)

- Purity

- High-purity Polyurethane Foam core

- Installation Type

- Mechanical Fasteners/Concealed Fixing

- Load Capacity

- Up to 150-200 kg/m (varies with thickness/support)

- Features

- Fire retardant, weather resistant, sound insulation, energy efficient

- Application

- Industrial and commercial roofing systems

- Thickness

- 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm (custom options available)

- Material Grade

- IS 14246/ISO certified PPGI & CFC-Free PUF

- Form

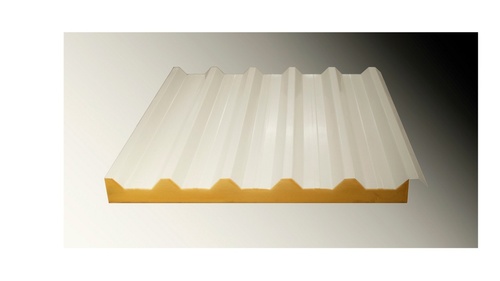

- Sandwich Panel

- Product Type

- Puf Roofing Panel

- Main Material

- Polyurethane Foam (PUF) with Pre-coated Galvanized Iron (PPGI) sheets

- Surface Treatment

- Color Coated / Pre-coated / Galvanized

- Size

- Customizable (Standard Width: 1000 mm; Length: up to 12 meters or as per requirement)

- Weight

- Approx. 10-15 kg/m (varies with thickness)

- Feature

- High thermal insulation, lightweight, leak proof, corrosion resistant

- Shape

- Trapezoidal

- Thermal Conductivity

- 0.024 W/mK

- Panel Density

- 402 kg/m (PUF Core)

- UV Resistance

- Superior, long-term color retention

- Bending Strength

- >1.0 kg/cm

- Compressive Strength

- >0.15 N/mm (at 10% deformation)

- Water Absorption

- < 1.5% by volume

- Fire Resistance

- Self-extinguishing, Class 1 as per IS standard

- Joint Type

- Tongue & Groove or Overlap joint for leak-proof construction

- Service Life

- Over 25 years (with proper maintenance)

- Sound Insulation

- Up to 35 dB

- Metal Sheet Thickness

- 0.4 mm to 0.6 mm (top & bottom sheet)

- Moisture Resistance

- Excellent

- Temperature Resistance

- -40C to +80C

Puf Roofing Panel Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Puf Roofing Panel

Having rich expertise in this domain, we are betrothed in offering the best grade array of PUF Roofing Panel. This panel is manufactured using top quality polyurethane foam and contemporary high pressure casting methods by our ingenious professionals. Provided panel is suitable for roof insulation to maintain the temperature of cold storage chamber, clean room and other residential as well as commercial buildings. The offered PUF Roofing Panel is available for our valuable patrons at reasonable prices.

Features:

- Robust design

- Easy to install

- Waterproof

- Longer life

Unmatched Thermal Insulation

PUF Roofing Panels deliver superior thermal insulation with a conductivity rating of 0.024 W/mK. This exceptional insulation keeps interiors comfortable, significantly reducing energy costs for temperature control in industrial, commercial, or cold storage environments. Their fire-retardant and moisture-resistant properties add greater safety and performance to your projects.

Durable and Leak-Proof Construction

Built with tongue & groove or overlap joints, these panels offer a leak-proof solution ideal for roofing systems exposed to variable weather. The robust PPGI sheets and PUF core ensure long-term durability, while the surface treatment options provide lasting color retention and corrosion resistance, keeping buildings protected for decades.

Versatile Application and Easy Installation

PUF Roofing Panels are expertly designed for a wide range of uses including prefabricated roofing and insulation in warehouses, commercial buildings, and cold storages. Their trapezoidal shape and customizable sizes simplify installation, making them suitable for various architectural requirements and load capacities up to 200 kg/m.

FAQs of Puf Roofing Panel:

Q: How are PUF Roofing Panels installed to ensure a leak-proof roofing system?

A: PUF Roofing Panels are installed with mechanical fasteners or concealed fixing methods. Their tongue & groove or overlap joint system provides seamless integration between panels, effectively preventing water penetration and ensuring reliable leak-proof performance.Q: What benefits does the PUF core provide in terms of thermal insulation and energy efficiency?

A: The high-purity polyurethane foam (PUF) core offers excellent thermal insulation with a thermal conductivity of 0.024 W/mK. This minimizes heat transfer, making interiors more comfortable and lowering energy consumption for heating or cooling in industrial and cold storage spaces.Q: Where can PUF Roofing Panels be used most effectively?

A: PUF Roofing Panels are best suited for roofing in industrial and commercial buildings, cold storage insulation, warehouses, and prefabricated structures. Their adaptability and robust construction make them ideal for environments that demand high thermal efficiency and weather resistance.Q: What thickness and size options are available for custom projects?

A: The panels are customizable in thicknesses ranging from 30 mm to 100 mm, with a standard width of 1000 mm and lengths up to 12 meters or as required. This flexibility allows you to select the most appropriate panel configuration for your projects specific needs.Q: What is the expected service life of PUF Roofing Panels, and how can they be maintained?

A: With proper maintenance, such as regular inspections and cleaning, PUF Roofing Panels are engineered to deliver a service life of over 25 years. Their durable materials and protective coatings ensure longevity in various environmental conditions.Q: How do the panels perform in terms of fire and sound resistance?

A: PUF Roofing Panels are self-extinguishing and compliant with Class 1 fire resistance as per IS standards, enhancing building safety. They also provide sound insulation up to 35 dB, helping to reduce noise intrusion and improve indoor comfort.Q: What surface treatment options are available and how do they enhance durability?

A: Panel surfaces can be color coated, pre-coated, or galvanized, ensuring superior UV resistance, long-term color retention, and enhanced protection against corrosion and environmental wear. These treatments contribute to the panels extended lifespan and aesthetic appeal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Sandwich Panel Category

Air Handling Units For Hvac Industries

Minimum Order Quantity : As per order Piece

Installation Type : Floor Mounted / Ceiling Suspended

Size : Customized / Standard Sizes Available

Color : White / Grey / Customized

Feature : Energy Efficient, High Performance, Durable

Usage : HVAC Air Distribution and Treatment

Roofing Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Installation Type : Interlocking / Overlapping Joint System

Size : Length: Customized (up to 12 meters); Width: Standard 1000 mm

Color : Blue, White, Green, Grey, as per requirement

Feature : High Insulation, Weather Resistance, Light Weight

Usage : Industrial/Commercial/Residential Roofing

Cold Storage Puf Sandwich Panel

Minimum Order Quantity : As per order , , Piece

Installation Type : Tongue and Groove Joint with Cam Lock System

Size : Standard and Custom Sizes (Height and Width as per requirement)

Color : White/Grey/Customized

Feature : High Insulation, Durable, Fire Retardant

Usage : Cold Rooms, Ripening Chambers, Fruit and Vegetable Storage

Room Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Installation Type : Interlocking tongue and groove or cam lock system

Size : Customizable (Standard: 1.2 m width x up to 12 m length)

Color : White, blue, grey, or as per requirement

Feature : High thermal insulation, fire resistance, easy installation

Usage : Thermal and acoustic insulation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free