Air Handling Units For Hvac Industries

Air Handling Units For Hvac Industries Specification

- Machines Type

- Air Handling Equipment

- Form

- Assembled Unit

- Installation Type

- Floor Mounted / Ceiling Suspended

- Thickness

- 18-24 Gauge (Panel Thickness 25-50 mm)

- Diameter

- Depends on Blower and Coil Size

- Application

- Commercial and Industrial Buildings, Hospitals, Offices

- Color

- White / Grey / Customized

- Features

- Double Skin Construction, Anti-Corrosion, Noise Reduction

- Material Grade

- SS304 / GI / Premium Quality

- Load Capacity

- 1000-30000 CFM

- Usage

- HVAC Air Distribution and Treatment

- Product Type

- Air Handling Unit

- Main Material

- Galvanized Steel / Stainless Steel

- Surface Treatment

- Powder Coated / Polished

- Size

- Customized / Standard Sizes Available

- Weight

- Varies with Model (Approx. 250-1200 kg)

- Feature

- Energy Efficient, High Performance, Durable

- Shape

- Rectangular / Modular

- Insulation Material

- PUF / Rockwool (25-50 mm)

- Temperature Range

- -10C to 55C

- Service Life

- 15+ Years (with proper maintenance)

- Humidity Control

- Yes, Optional

- Frame Material

- Aluminium Extruded Frame

- Access Panels

- Hinged / Removable Type for Maintenance

- Coil Type

- Chilled Water / DX Coil / Hot Water Coil

- Filter Type

- Pre, Fine, HEPA filters available

- Air Leakage Class

- Class B / C

- Motor Type

- IE2/IE3 Efficiency, Belt/Direct Driven

- Voltage

- 220-415 V, 3 Phase, 50 Hz

- Static Pressure

- Up to 1000 Pa

- Panel Construction

- Double Skin with Aluminium Profiles

- Fan Type

- Forward / Backward Curved Centrifugal Fan

Air Handling Units For Hvac Industries Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Air Handling Units For Hvac Industries

AIR HANDLING UNITS FOR HVAC INDUSTRIES:

We manufacture and supply optimum quality Air Handling Units that are widely used in a large variety of industries. We use for

air handling units are manufactured from premium grade of raw material and are available in a variety of sizes according to the

specification of the clients.

Superior Features: -

Rigid framework design has inherent strength and stability.

The aluminium profiles are corrosion resistant with specially designed three way corners.

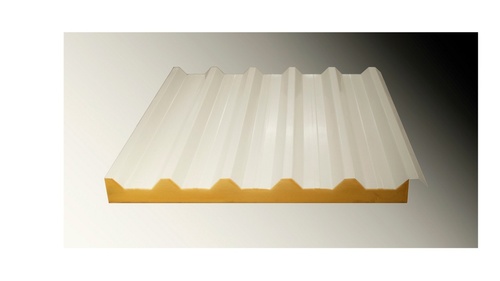

The panels are pressure injected with CFC free polyurethane foam up to 40 Kg/cum densities.

The panels are compact in design to provide vibration-free, noiseless performance and are easily maintainable.

PRODUCT DETAILS

LENGTH UP TO 6MTR.

WIDTH UP TO 1.2MTR

THICKNESS- 25MM TO 150MM.

NOTE- 25MM TO 40MM THICKNESS AVAILABLE UP TO CERTAIN LENGTH.

DENSITY 40KG/M3

Available in PUR and PIR.

FACING

GI PRE COATED

SS

ALUMINIUM ETC.

ADVANTAGES / BENIFITS

THIN WALLS

OPTIMUM INSULATION WITHOUT THERMAL BRIDGES

COMPONENTS CAN BE DISASSEMBLED AND REUSED

OUTSTANDING LOAD BEARING CAPACITY

HYGENIC FOR FOOD PRESERVATION

ODORLESS

LONG LIFE AND DURABLE

RESISTANT TO MOST OILS , CHEMICALS AND SOLVENTS

FIRE RESISTANT.

Advanced Double-Skin Construction

Our AHUs are built with double-skin panels comprising aluminium extruded frames and insulated with high-quality PUF or Rockwool. This structure ensures enhanced durability, significant noise reduction, and thermal efficiency. The anti-corrosive surface treatment (powder-coated or polished) guarantees a long-lasting finish even in demanding environments. Access panels, either hinged or removable, provide easy maintenance and safe interior access, extending the units life beyond 15 years with proper care.

Customizable Performance and Filtration

Each unit is engineered for flexibility, offering forward/backward curved centrifugal fans and a range of filters (Pre, Fine, HEPA) to meet diverse air purity standards. Coil options include chilled water, DX, or hot water, adapting the AHU for different climates and building requirements. Our air handling units cater to a wide capacity range (100030000 CFM) and are available in standard or custom sizes to suit both commercial and industrial applications.

FAQs of Air Handling Units For Hvac Industries:

Q: How do I select the right air handling unit for my HVAC project?

A: Choosing the right AHU depends on your building size, airflow requirements (100030000 CFM), filtration needs (Pre, Fine, and HEPA), and coil type (chilled water, DX, or hot water). Factors like installation type (floor-mounted or ceiling-suspended), static pressure requirements (up to 1000 Pa), and available voltage (220415 V, 3 phase) also influence the decision. Consulting with our technical team ensures the optimum configuration for your application.Q: What are the benefits of double-skin construction and insulated panels?

A: Double-skin construction with 2550 mm PUF or Rockwool insulation enhances energy efficiency by reducing thermal losses, minimizes operational noise, and boosts the AHUs durability. This design protects against external temperature fluctuations and helps maintain consistent air quality, making the system suitable for sensitive environments such as hospitals and cleanrooms.Q: When should filters be replaced or maintained in the AHU?

A: Filter maintenance frequency depends on the usage and ambient air quality. Pre-filters typically require inspection and cleaning every 13 months, while Fine and HEPA filters may last longer but should be checked at least every 6 months. Following the recommended maintenance schedule and easy access through hinged or removable panels ensures optimal air quality and extends system life.Q: Where can these air handling units be installed?

A: Our AHUs are versatile and suitable for commercial and industrial buildings, hospitals, offices, and specialized facilities where precise climate and air quality control are essential. They are designed for both floor-mounted and ceiling-suspended installations and can be customized to fit various architectural constraints.Q: What is the typical lifespan and service life of these AHUs?

A: With robust construction using galvanized steel or stainless steel (SS304/GI) and premium insulation, our units offer a service life of over 15 years when maintained regularly. The anti-corrosion surface treatment and modular design further enhance longevity, ensuring reliable performance throughout the products lifetime.Q: How does the AHU control humidity and maintain comfortable indoor environments?

A: Humidity control is featured as an optional function in our AHUs. The system maintains optimal indoor humidity by integrating appropriate coils (chilled water, DX, or hot water) and enabling precise control over airflow and temperature, crucial for sensitive spaces like hospitals and laboratories.Q: What are the key benefits of using energy-efficient IE2/IE3 motors and advanced fans in these units?

A: High-efficiency IE2/IE3 motors and aerodynamic fan designs (forward/backward curved) contribute to lower energy consumption, reduced operational costs, and quieter operation. This makes the system environmentally friendly while delivering reliable air distribution and maintaining stringent HVAC standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Sandwich Panel Category

Puf Roofing Panel

Minimum Order Quantity : As per order Piece

Thickness : 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm (custom options available)

Installation Type : Mechanical Fasteners/Concealed Fixing

Form : Sandwich Panel

Machines Type : Panel Forming Machine

Color : Available in multiple colors (red, blue, green, white, etc.)

Ahu Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Thickness : 30 mm, 40 mm, 50 mm, 60 mm, up to 150 mm

Installation Type : Modular, Prefabricated Assembly

Form : Panel Sheets

Machines Type : Sandwich Panel ProductionFoaming Machines

Color : White / Off White / Customized

Roofing Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Thickness : 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm (customizable)

Installation Type : Interlocking / Overlapping Joint System

Form : Sandwich Panel Sheets

Machines Type : Roof Panel Roll Forming Machine

Color : Blue, White, Green, Grey, as per requirement

Room Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Thickness : 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm (as required)

Installation Type : Interlocking tongue and groove or cam lock system

Form : Panel sheet

Machines Type : Panel production and installation machinery

Color : White, blue, grey, or as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free