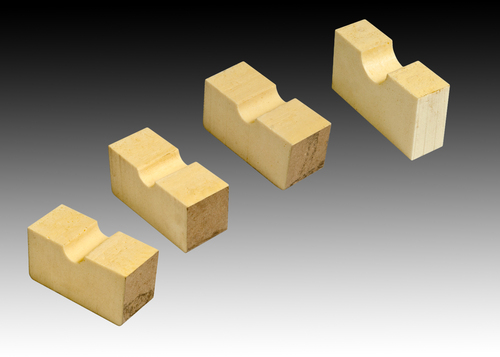

Square PUF Pipe Support

Square PUF Pipe Support Specification

- Size

- From 15 mm pipe OD onwards; customizable size available

- Installation Guideline

- Place square support under pipe, secure with clamps or welding as per the system design

- Surface Treatment

- Galvanized/Aluminum Sheet Finish

- Density

- 40 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- 0.024 0.028 W/mK (PUF core)

- Feature

- High insulation, rigid support, moisture resistance

- Coating Type

- Metallic sheet (GI or Aluminum)

- Product Type

- Square PUF Pipe Support

- Material

- Polyurethane Foam (PUF) core with galvanized iron or aluminum sheet

- Tensile Strength

- >3 kg/cm

- Width

- As per pipe outer diameter (customizable)

- Thickness

- Standard: 50 mm / Customizable

- Application

- Supporting and insulating pipes in HVAC, refrigeration, petroleum, and chemical industries

- Heat Conductivity

- Low

- Color

- Yellow/Off White

- Applicable Standards

- ASTM C1029, IS: 12436

- Insulation Grade

- Class 1 (Excellent)

- Packaging Type

- Shrink Wrapped or Carton Packed

- UV Resistance

- Superior (with aluminum cladding)

- Corrosion Resistance

- High (due to metal cladding)

- Weight

- Lightweight

- Pipe Size Compatibility

- Suitable for 0.5" to 24" OD pipes

- Shape

- Square

- Compression Strength

- >2.5 kg/cm²

- Edge Type

- Smooth / Chamfered

- Water Absorption

- <2% by volume

Square PUF Pipe Support Trade Information

- Supply Ability

- 01 , , Piece Per Month

- Delivery Time

- 1-4 Week

About Square PUF Pipe Support

Being a prominent entity, we are engaged in manufacturing, exporting and supplying excellent quality Square PUF Pipe Support. Ideal to prevent direct heat transfer between pipes, this support is fabricated under the vigilance of dexterous professionals in square shape by utilizing pristine grade polyurethane. It is used for fixing pipe at certain angle or position. Besides, the offered support is known for high strength, durability and flexibility. Our clients can avail the provided Square PUF Pipe Support from us at budget friendly rates.

Key Points:

- Strong structure

- Leak proof

- Easy to install

- Flawless finish

AVAILABLE IN PUR AND PIR

PRODUCT DETAILS

- Pipe Size 1/4' to Above

- Thickness- 25mm and above.

- Length- 25mm and above

- Density - 100kg/m3 to 500kg/m3

NOTE: SHAPES AND SIZES AS PER CUSTOMER REQUIREMENTS CAN BE MANUFACTURED.

AVAILABLE SHAPES

- Degree SUPPORTS (60 DEGREE TO 120 DEGREE)

- Round SUPPORTS

- Square SUPPORTS

Engineered for Superior Pipe Support

Our Square PUF Pipe Support is uniquely designed to combine high insulation properties with rigid structural strength. The metal claddingavailable in galvanized iron or aluminumguards against corrosion and UV degradation, extending service life in challenging environments. Its low moisture absorption and high compression resistance make it suitable for both indoor and outdoor installations.

Customizable for Versatile Pipe Applications

Available for pipe sizes ranging from 0.5" to 24" outer diameter, this support can be customized in width and thickness to suit various operational requirements. The smooth or chamfered edges promote safe installation, while packaging options like shrink-wrapping and carton packing ensure secure transit and storage.

Easy Installation and Maintenance

Square PUF Pipe Supports are engineered for effortless installation underneath pipes and can be secured with clamps or welded as per the system specifications. The rigid, moisture-resistant PUF core assures long-term stability and minimal maintenance for your piping infrastructure.

FAQs of Square PUF Pipe Support:

Q: How do you install Square PUF Pipe Supports in a piping system?

A: To install the Square PUF Pipe Support, place it directly beneath the pipe and secure it using suitable clamps or welds, depending on your systems design. Its smooth or chamfered edge options help ensure a proper fit during installation.Q: What are the main benefits of using PUF Pipe Supports with metal cladding?

A: The combination of polyurethane foam core and galvanized iron or aluminum cladding provides excellent thermal insulation, high mechanical strength, resistance to moisture, superior corrosion protection, and enhanced durability in UV-exposed settings.Q: When should Square PUF Pipe Supports be used?

A: These supports are ideal for use in HVAC, refrigeration, petroleum, and chemical industries whenever superior insulation and pipe stability are critical, especially where moisture resistance and protection against corrosion are required.Q: Where can Square PUF Pipe Supports be applied?

A: They are suitable for all pipeline installations exposed to changing environments, such as rooftops, chemical plants, refrigeration lines, and industrial facilities, ensuring reliable support for pipes ranging from 0.5" to 24" outer diameter.Q: What is the process for customizing the size and thickness of these supports?

A: Customization is straightforwardsimply specify the pipes outer diameter and any required width or thickness adjustments when placing your order. The supports are manufactured to closely fit your specific pipeline dimensions.Q: What makes this pipe support highly resistant to corrosion and UV exposure?

A: The use of high-quality galvanized iron or aluminum cladding provides a metallic barrier, protecting the insulation core from corrosion, harsh weather, and ultraviolet radiation, even during prolonged outdoor usage.Q: What standards do Square PUF Pipe Supports comply with?

A: These supports comply with ASTM C1029 and IS: 12436 standards, ensuring they meet stringent requirements for insulation grade, compressive strength, density, and overall quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Pipe Support & Clamp Category

Puf Pipe Support

Minimum Order Quantity : As per order , , Piece

Color : Yellow

Layer : Single or Multiple as per requirement

Installation Guideline : Mount pipe support on clean surface, align with pipe size, secure with clamps

Material : Polyurethane Foam (PUF)

Thickness : 50 mm

Degree Puf Pipe Support

Minimum Order Quantity : As per order , , Piece

Color : Light Yellow/Cream

Layer : Single, Double or Multi Layer (depending on application)

Installation Guideline : Installed at pipe supports/joints, fixed with clamps or fasteners

Material : Puf (Polyurethane Foam)

Thickness : 25 mm 100 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free