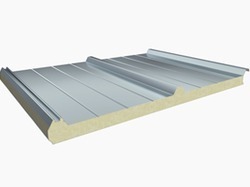

Polyurethane Roof Panels

Polyurethane Roof Panels Specification

- Machines Type

- Panel Roll-Forming Machines

- Color

- White, Blue, Grey, Customized

- Form

- Sandwich Panel

- Thickness

- 30 mm to 150 mm

- Installation Type

- Screw Down / Concealed Fastener

- Load Capacity

- Up to 250 kg/m (Depending on panel configuration)

- Features

- Waterproof, Fire Resistant, Soundproof, Durable

- Usage

- Industrial, Commercial, Residential Roofing

- Purity

- Polyurethane purity > 95%

- Material Grade

- Polyurethane Core Grade: PUR/PIR A-grade, Metal Grade: Galvanized/Aluminum

- Application

- Pre-engineered Buildings, Warehouses, Factories, Cold Storage

- Product Type

- Polyurethane Roof Panels

- Main Material

- Polyurethane Foam with Metal (Steel/Aluminum) Facing

- Surface Treatment

- Pre-painted / Coated / Embossed Surface

- Size

- Standard Length: 2 to 12 meters, Width: 1000 mm nominal

- Weight

- 5-15 kg/m (Depends on thickness and metal type)

- Feature

- Lightweight, Thermal Insulation, High Strength

- Shape

- Trapezoidal / Corrugated Panel

- Fire Rating

- Class B-s2-d0 (EN 13501-1)

- Edge Detail

- Sealed, Anti-Leak Design

- UV Resistance

- High

- Compressive Strength

- >150 kPa

- Water Absorption

- < 1% by volume

- Packaging

- Wrapped in PE Film & Palletized

- Density

- 40-45 kg/m PU Core

- Panel Joint Type

- Tongue and Groove / Cam Lock System

- Light Transmission

- Opaque

- Thermal Conductivity

- 0.023 W/mK

- Service Temperature Range

- -40C to +80C

- Corrosion Resistance

- Excellent

Polyurethane Roof Panels Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Polyurethane Roof Panels

Product Description:

We are offering wide range of Polyurethane Roof Panel. This roofing panel is designed using most favorable material and updated technology according with the market norms at our manufacturing unit. Patrons can take the complete assortment of sandwich panel from us at reasonable rates.

- Accurate dimension

- Low maintenance

- Compact design

Superior Thermal Insulation

Engineered for extreme temperature efficiency, these panels achieve a thermal conductivity as low as 0.023 W/mK, keeping interiors comfortable and energy consumption low. The polyurethane foam core ensures minimal heat transfer, optimizing building insulation in a variety of climate conditions.

Exceptional Structural Strength

Manufactured with a high-density polyurethane core and a compressive strength greater than 150 kPa, the panels provide excellent load-bearing capacity up to 250 kg/m depending on configuration. Their advanced panel joint systems, such as tongue-and-groove and cam lock, enhance rigidity and prevent leakage.

Reliable Fire and Weather Resistance

Certified with a Class B-s2-d0 fire rating to EN 13501-1, these panels offer dependable resistance against fire. Their robust metal facings and UV-resistant coatings provide outstanding protection from harsh weather, corrosion, and degradation over time.

FAQs of Polyurethane Roof Panels:

Q: How are polyurethane roof panels installed?

A: Polyurethane roof panels are designed for ease of installation, using either screw-down or concealed fastener methods. The tongue-and-groove or cam lock panel joints ensure tight, secure connections that reduce leaks. Panels are sized for standard roofing systems, and edges are sealed for added weather protection.Q: What applications are suitable for these roof panels?

A: These panels are widely used in industrial, commercial, and residential roofing, including pre-engineered buildings, warehouses, factories, and cold storage facilities. Their thermal insulation, waterproof, and fire-resistant properties make them suitable for diverse project requirements.Q: When is it recommended to use panels with a higher thickness?

A: Thicker panels, up to 150 mm, are ideal when higher thermal insulation or increased structure load capacity is needed, such as in cold storage or areas with extreme weather conditions. The required thickness depends on climatic exposure and building use.Q: Where can I source customized color or size panels?

A: Customization in length (212 meters), width (nominal 1000 mm), thickness (30150 mm), and color (white, blue, grey, and other options) can be arranged directly with the manufacturer or supplier in India, depending on project specifications.Q: What is the benefit of the sandwich panel structure?

A: The sandwich construction, with a high-purity polyurethane core and metal facings, delivers superior insulation, strength, and durability while remaining lightweight. This combination ensures longer lifespan, energy savings, and reduced maintenance costs.Q: How do these panels perform in harsh environments?

A: Engineered with excellent UV and corrosion resistance, these panels maintain structural and visual integrity when exposed to intense sunlight or moisture. Their dense core and sealed edges prevent water absorption (<1% by volume), ensuring reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Panels Category

Polyurethane Roof Panel

Minimum Order Quantity : As per order Piece

Form : Sandwich panel

Thickness : 30mm, 50mm, 75mm, 100mm (customizable)

Load Capacity : Designed to withstand roof load and wind pressure (varies by thickness and application)

Installation Type : Screw or clip fixed

Features : Fire resistance, waterproofing, sound insulation, highly durable

PUF Sandwich Panel

Minimum Order Quantity : As per order Piece

Form : Panel

Thickness : 30mm, 40mm, 50mm, 60mm, 80mm, 100mm (Customizable)

Load Capacity : Variable (Depends on thickness and use)

Installation Type : Prefabricated / Modular

Features : Fire Resistant, Water Proof, Sound Insulation

Insulated Roofing Panel

Minimum Order Quantity : As per order Piece

Form : Panel

Thickness : 30mm, 50mm, 60mm, 80mm, 100mm (custom on request)

Load Capacity : High Structural Load Bearing Capacity

Installation Type : SelfDrilling Fastener / Nut Bolt Fixing

Features : Fire Retardant, Sound Insulation, Corrosion Resistant, UV Resistant, Durable

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free