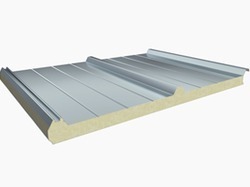

Polyurethane Cold Room Panel

Polyurethane Cold Room Panel Specification

- Usage

- Commercial and Industrial Refrigeration

- Load Capacity

- High Load Bearing Capacity

- Machines Type

- Insulation Panel Production Line Compatible

- Application

- Cold Rooms, Freezer Rooms, Warehouses, Clean Rooms

- Purity

- High-density PU Core

- Color

- White, Grey, Custom Colors Available

- Installation Type

- Interlocking (Tongue and Groove System)

- Material Grade

- Food Grade

- Thickness

- 50mm, 75mm, 100mm, 120mm, 150mm, 200mm

- Form

- Solid Panel

- Features

- Moisture Proof, Lightweight, Durable, Corrosion Resistant, Energy Saving

- Product Type

- Polyurethane Cold Room Panel

- Main Material

- Polyurethane (PU) Foam

- Surface Treatment

- Pre-painted Galvanized Steel Sheet

- Size

- Standard Panel Size, Customization Available

- Weight

- Approx. 40-45 kg/m (Depending on Thickness)

- Feature

- Excellent Thermal Insulation, Fire Resistance, High Strength

- Shape

- Rectangular Panel

- Edge Type

- Tongue and Groove with Camlock

- Environmental Compliance

- CFC-Free, Eco-Friendly

- Anti-bacterial Coating

- Available on Request

- Service Temperature

- -40C to +80C

- Packaging Type

- Standard Export Packing

- Water Absorption

- 2% by Volume

- Thermal Conductivity

- 0.023 W/mK

- Fire Rating

- B1/B2 (Optional)

- Humidity Resistance

- Excellent

- Panel Facing Thickness

- 0.4mm 0.7mm

- Compressive Strength

- >150 kPa

- Density

- 40-42 kg/m (PU Core)

- Panel Length

- Up to 12 meters (Custom Length Available)

Polyurethane Cold Room Panel Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Polyurethane Cold Room Panel

Having rich expertise in this field, we are able to provide pristine grade Polyurethane Cold Room Panel in different specifications. Manufactured under the strict guidance of adroit professionals, the provided panel is known for its high strength and longevity. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc. We offer this Polyurethane Cold Room Panel in different sizes as per the ever-evolving requirements of our patrons.

Features:

- Damage proof

- Highly durable

- Robust design

- Fine finish

Specifications:

- Length:Up to 6mtr

- Width:Up to 1.2mtr

- Thickness:25mm to 150mm

- Note 25mm to 40mm thickness

- Available up to certain length

- Tongue and Groove with specially

- designed CAM LOCKS provided

- Density:40kg/m3

Other Details:

- Rigidly and good weatherproofing

- Twice the insulation characteristics as polystyrene or other thinner insulation panels

- Better transportability

- More cold storage volume for a given space

- Ease and speed of cold storage unit installation

Advantages:

- Thin walls

- Optimum insulation without thermal bridges

- Components can be disassembled and reused

- Hygienic for food preservation

- Odorless

- Long life and durable

- Resistant to most oils, chemicals and solvents

- Fire resistant

Superior Insulation Performance

Designed with a high-density polyurethane (PU) core, these cold room panels boast thermal conductivity as low as 0.023 W/mK. Such excellent insulation significantly reduces energy consumption, maintaining precise temperature control for cold rooms, freezer rooms, and warehouse facilities.

Robust Fire Resistance & Safety

These panels can be configured with B1/B2 fire ratings, ensuring increased protection without compromising on performance. Their pre-painted galvanized steel surface, coupled with optional anti-bacterial coating, guarantees food safety and hygienic operations, making them ideal for food-grade environments.

Customizable & Eco-Friendly Solutions

Offering panel lengths up to 12 meters and thicknesses from 50mm to 200mm, we can tailor the size, color, and finish to your requirements. Manufactured with CFC-free PU foam, the panels are environmentally friendly and comply with global standards, suitable for a wide range of applications.

FAQs of Polyurethane Cold Room Panel:

Q: How are Polyurethane Cold Room Panels installed for optimal insulation?

A: These panels use a tongue and groove interlocking system equipped with camlocks, which ensures airtight joining and minimizes thermal bridging. Installation is straightforward and efficient, facilitating rapid assembly for both standard and custom cold room designs.Q: What are the benefits of choosing panels with a high-density PU core?

A: The panels high-density (40-42 kg/m) PU core provides superior thermal insulation, high compressive strength (>150 kPa), and excellent humidity resistance. This results in lower operational costs, extended lifespan, and reliable performance even in demanding environments.Q: When is an anti-bacterial coating recommended for these panels?

A: An anti-bacterial coating is recommended in food processing areas, pharmaceutical cold storages, and clean rooms where hygiene standards are paramount. This optional feature helps prevent microbial growth and supports compliance with industry health regulations.Q: Where can these insulation panels be used effectively?

A: Polyurethane Cold Room Panels are suitable for commercial and industrial refrigeration, cold rooms, freezer rooms, warehouses, and clean rooms. Their corrosion-resistant, moisture-proof construction also makes them ideal for food storage and pharmaceutical applications.Q: What makes these panels environmentally friendly?

A: The panels are manufactured using CFC-free PU foam, reducing environmental impact. Their energy-saving design minimizes power consumption over time, while the use of recyclable pre-painted galvanized steel further supports eco-friendly practices.Q: How does the panel thickness affect its performance and application?

A: Panel thicknesses range from 50mm to 200mm, allowing selection based on insulation requirements and temperature ranges. Thicker panels are ideal for sub-zero freezer storage, while standard sizes are sufficient for chiller and warehouse use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Panels Category

Ceiling Panels

Minimum Order Quantity : As per order Piece

Features : Moisture Resistant, Easy to Clean

Thickness : 6 mm

Material Grade : Premium Quality PVC

Form : Panel

Installation Type : Suspended/Drop Ceiling

Insulated Roofing Panel

Minimum Order Quantity : As per order Piece

Features : Fire Retardant, Sound Insulation, Corrosion Resistant, UV Resistant, Durable

Thickness : 30mm, 50mm, 60mm, 80mm, 100mm (custom on request)

Material Grade : ASTM A653 / IS 277

Form : Panel

Installation Type : SelfDrilling Fastener / Nut Bolt Fixing

Polyurethane Roof Panel

Minimum Order Quantity : As per order Piece

Features : Fire resistance, waterproofing, sound insulation, highly durable

Thickness : 30mm, 50mm, 75mm, 100mm (customizable)

Material Grade : Polyurethane grade suitable for insulation applications

Form : Sandwich panel

Installation Type : Screw or clip fixed

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free