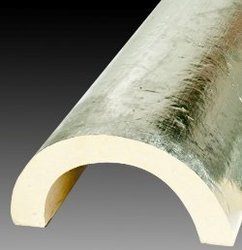

Puf Pipe Section

Puf Pipe Section Specification

- Thermal Conductivity

- 0.0220.024 W/mK

- Density

- 40 Gram per cubic centimeter(g/cm3)

- Surface Treatment

- Plain / Aluminum foil / Kraft paper / GI sheet clad

- Size

- Custom sizes as per pipe diameter

- Installation Guideline

- Can be clamped or glued directly onto pipes; secure joints with adhesive tape or cladding

- Material

- Polyurethane Foam (PUF)

- Tensile Strength

- >1.0 kg/cm

- Width

- Variable as per pipe diameter

- Thickness

- 25 mm to 100 mm

- Application

- Thermal insulation for piping in HVAC, refrigeration, oil & gas

- Heat Conductivity

- 0.0220.024 W/mK

- Color

- Yellow

Puf Pipe Section Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Puf Pipe Section

We are a noted as a renowned manufacturer, exporter and supplier of top grade PUF Pipe Section. The provided section is highly demanded in pharmaceutical, chemical and other industries for providing excellent insulation to pipelines. Available in numerous specifications, the offered section is manufactured using superior-quality polyurethane foam and contemporary techniques by our experts. Tested on several quality aspects, our valued patrons can avail this PUF Pipe Section at marginal rates within committed time frame.

Features:

- Excellent thermal insulation property

- Resistant to heat

- Abrasion resistance

- Simple to install

PRODUCT DESCRIPTION:

- Rigid PU foam cored Pipe sections manufactured and available in standard sizes have excellent thermal insulation properties and make a valuable contribution towards reducing energy consumption in various industries. PU foam cored Insulated Pipe Sections are manufactured with the help of a dedicated High Pressure equipment using state of art moulds and fixtures to consistently yield:

- Environment friendly CFC-free Polyurethane Foam of desired and uniform density

- Close cell content of over 90%

- Excellent dimensional & thermal insulation properties together with compressive strength this added dimension makes it a tit construction material OPIPL offers a wide range of READY TO APPLY Polyurethane foam core Insulated Pipe Section

FEATURES / ADVANTAGES :

- Superior insulating efficiency leading to energy savings.

- Void free insulation

- Durable

- Water and moisture resistant

- Dimensionally stable

- Resistant to most oils , chemicals , and solvents

- No thermal bridges

- Fire resistant

AVAILABLE IN PUR AND PIR

DETAILS OF PUF PIPE SECTION

- Pipe Size To 24

- Thickness- 25mm And Above.

- Length- 1000mm

- Density 36kg/M3 And Above.

For thickness above 100mm we offer pipe sections in double or triple layers as per customers requirement.

For Pipe Size over 24 we recommend Puf Sheets for Pipe Line insulation.

Exceptional Thermal Insulation

The PUF Pipe Section is engineered to minimize thermal losses in piping systems, thanks to its low thermal conductivity of 0.0220.024 W/mK. This property, combined with its stable dimensional profile under recommended temperatures, makes it a preferred choice for preserving energy and ensuring efficient system operation across HVAC, refrigeration, and oil & gas applications.

Durable and Safe Construction

Constructed from yellow polyurethane foam, the pipe section is both fire retardant and self extinguishing, offering enhanced protection in critical environments. Its robust compressive and tensile strength prevent deformation, while excellent moisture resistance contributes to long-lasting performance even in humid conditions.

Flexible Customization and Easy Installation

Available from " to 16" diameterand customizablethe PUF Pipe Section fits a variety of piping requirements. Thickness options range from 25 mm to 100 mm, and surface finishes include plain, aluminum foil, kraft paper, or GI sheet cladding. Installation is simple, using clamping or adhesive, and joints can be secured with tape or external cladding.

FAQs of Puf Pipe Section:

Q: How is the PUF Pipe Section installed onto existing piping systems?

A: PUF Pipe Sections can be clamped or glued directly onto pipes. For secure insulation, joints are sealed with adhesive tape or covered by external cladding, following the suggested guidelines.Q: What benefits does the fire retardant and self extinguishing feature offer?

A: These fire properties enhance safety by minimizing flame spread and allowing the material to self-extinguish when exposed to fire. This helps protect facilities and mitigates risks in industrial environments.Q: What chemical resistances does the PUF Pipe Section provide?

A: The pipe section resists most chemicals, including mild acids and alkalis, ensuring reliable performance in environments where such exposures may occur.Q: When is it recommended to use PUF Pipe Sections for insulation?

A: PUF Pipe Sections are ideal for projects requiring thermal insulation and moisture resistance, commonly used in HVAC, refrigeration, and oil & gas piping installations.Q: Where can custom-sized PUF Pipe Sections be sourced?

A: Custom sizes are available directly from manufacturers, exporters, and suppliers based in India, catering to specific project requirements regarding pipe diameters and insulation thickness.Q: What is the typical service life of the PUF Pipe Section under normal conditions?

A: Under recommended operating conditions, PUF Pipe Sections have a service life of more than 10 years, delivering sustained insulation performance.Q: How does the moisture resistance benefit the usage of PUF Pipe Sections?

A: Excellent moisture resistance ensures the insulation remains effective and does not degrade in damp environments, preserving energy efficiency and reducing maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Pipe Section Category

PIR Pipe Sections

Minimum Order Quantity : As per order Piece

Application : Thermal insulation of HVAC, refrigeration, chilled water, and process piping

Feature : Closed cell structure, CFC and HCFC free, dimensionally stable

Width : From DN 15 mm up to DN 400 mm

Tensile Strength : 200 kPa

Layer : Single or multiple, as per thickness requirement

Polyurethane Foam Pipe Section

Minimum Order Quantity : As per order Piece

Application : Thermal insulation of pipelines for HVAC, chilled water, refrigeration, chemical plants, oil & gas industries

Feature : High thermal resistance, low water absorption, lightweight, easy to install

Width : Customizable as per Pipe OD

Tensile Strength : 120 kPa

Layer : Single or Multiple Layer

Pipe Section

Minimum Order Quantity : As per order Piece

Application : Thermal insulation of pipelines for chillers, HVAC, process industries, and refrigeration systems

Feature : High insulation value, lightweight, moisture resistant, fire retardant

Width : Customizable as per requirement

Tensile Strength : 0.20 0.30 N/mm

Layer : Single or multilayer as required

Polyurethane Pipe Section

Minimum Order Quantity : As per order Piece

Application : Thermal insulation for hot and cold pipelines in HVAC, process industries, oil & gas, chemical plants, refrigeration

Feature : Closed cell structure, high thermal resistance, CFC free, moisture resistance

Width : Varies as per pipe diameter

Tensile Strength : 0.150.30 MPa

Layer : Single or Multiple layers as required

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS