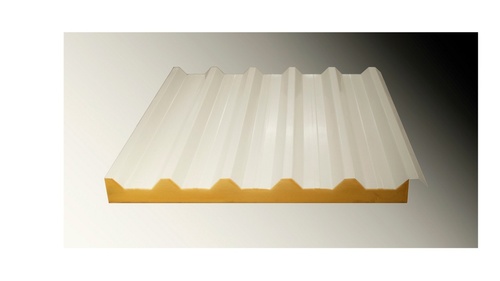

PortaCabin Puf Sandwich Panel

PortaCabin Puf Sandwich Panel Specification

- Material Grade

- Industrial grade PUF, IS: 12436 standard

- Thickness

- 30mm, 40mm, 50mm, 75mm, 100mm or as required

- Load Capacity

- High load bearing capacity (varies with thickness)

- Usage

- Temporary and permanent structures

- Color

- White, Blue, Grey, Custom colors available

- Form

- Sheet/Panel

- Features

- Fire retardant, Soundproof, Moisture resistant

- Machines Type

- Panel forming machinery

- Installation Type

- Prefabricated, Easy to assemble

- Purity

- High purity PU foam core

- Application

- Modular buildings, Construction sites, Guard rooms, Temporary shelters

- Product Type

- PortaCabin PUF Sandwich Panel

- Main Material

- PUF (Polyurethane Foam), GI sheet/PPGI sheet

- Size

- Customized as per requirement

- Weight

- Lightweight (varies based on thickness and size)

- Feature

- Thermal insulation, Quick installation, Durable, Weather resistant

- Shape

- Rectangular, Panel form

PortaCabin Puf Sandwich Panel Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About PortaCabin Puf Sandwich Panel

With nineteen years of domain knowledge, we are successfully catering to the diverse demands of the customers by manufacturing and supplying flawless PortaCabin Puf Sandwich Panel. We provide this panel in 25 mm to 40 mm thickness and width up to 1.2 mtr. To meet varied demands of the customers, we also personalize these panels as per the diverse demands of the customers. Our offered PortaCabin Puf Sandwich Panels have been designed by our professionals in an excellent manner using best-in-class raw materials.

Features:

- Dimensional accuracy

- Superior finish

- Durable

- Longer functional life

Other Details:

Product Details-

Length - Up to 6mtr.

Thickness- 25mm to 150mm.

Tongue and Groove with specially designed CAM LOCKS.

Density -40kg/m3

Facing

GI Pre coated

SS

Bituminous Paper

Aluminium Foil Paper

Kraft Paper

Ply

FRP Sheets.

Aluminium etc.

Superior Insulation and Durability

Engineered for excellent thermal performance with a thermal conductivity of just 0.0220.024 W/mK, these sandwich panels help maintain comfortable indoor conditions and reduce energy costs. The PUF core, combined with robust surface finishes, delivers long-lasting durability, as well as high resistance to weather, fire, moisture, and sound infiltration.

Quick and Versatile Installation

PortaCabin Puf Sandwich Panels feature a tongue & groove interlocking system, enabling easy, rapid assembly and tight joints for improved structural integrity. The modular approach makes them suitable for diverse applications, including construction sites, modular offices, guard rooms, and temporary shelters, and allows for custom sizing to fit specific project requirements.

Compliance and Quality Assurance

As an ISO 9001:2015 certified product with CE marking, these panels meet stringent international standards for quality and safety. Manufactured using precision machinery and high-purity materials, they offer consistent performance, high compressive strength, and a reputable lifespan, making them ideal for projects demanding reliability.

FAQs of PortaCabin Puf Sandwich Panel:

Q: How are PortaCabin Puf Sandwich Panels installed?

A: These panels are designed with a tongue & groove interlocking system, ensuring quick and secure assembly. Installation requires basic tools and can be performed by a small team, significantly reducing construction time for both temporary and permanent structures.Q: What makes the PortaCabin panels suitable for both temporary and permanent structures?

A: Their robust PUF core, high load capacity, and weather-resistant GI/PPGI outer layers give the panels the strength and durability needed for permanent applications, while their lightweight, modular design allows for easy dismantling and relocation in temporary setups.Q: When should I use PUF Sandwich Panels for my building projects?

A: PUF Sandwich Panels are ideal when your project needs efficient thermal insulation, quick installation, and modularitysuch as for modular buildings, site offices, guard rooms, or temporary shelters. They perform exceptionally well in both short-term and long-term installations.Q: Where are PortaCabin Puf Sandwich Panels commonly utilized?

A: These panels are widely applied in modular offices, construction sites, prefab homes, portable cabins, guard houses, and temporary facilities, offering versatility for diverse commercial, industrial, and residential environments.Q: What are the core benefits of using PortaCabin Puf Sandwich Panels?

A: Key benefits include excellent thermal and sound insulation, fire retardancy (Class B2/B3), low water absorption, high structural load-bearing capacity, and a durable lifespan exceeding 20 years under normal usage, all with rapid, flexible installation.Q: What certifications do PortaCabin Puf Sandwich Panels have?

A: The panels are certified to ISO 9001:2015 and bear the CE Mark, alongside meeting IS:12436 standards, ensuring compliance with stringent quality, safety, and performance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Puf Sandwich Panel Category

Ahu Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Machines Type : Sandwich Panel ProductionFoaming Machines

Installation Type : Modular, Prefabricated Assembly

Product Type : Ahu Puf Sandwich Panel

Feature : High Thermal Insulation, Fire Resistant, Lightweight

Features : Corrosion Resistant, High Thermal Stability, Sound Insulation

Roofing Puf Sandwich Panel

Minimum Order Quantity : As per order Piece

Machines Type : Roof Panel Roll Forming Machine

Installation Type : Interlocking / Overlapping Joint System

Product Type : Roofing Puf Sandwich Panel

Feature : High Insulation, Weather Resistance, Light Weight

Features : Fire Resistant, Thermal Insulation, Acoustic Insulation, Leak Proof

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS