Polyurethane Sandwich Panel

Polyurethane Sandwich Panel Specification

- Machines Type

- Panel forming and laminating lines

- Color

- White, off-white, blue, custom colors available

- Application

- Industrial building, cold rooms, warehouses, commercial structures

- Material Grade

- Galvanized steel grade as per IS/ASTM/EN standards

- Form

- Solid, sandwich panel

- Usage

- Insulated wall and roof panel, partitioning

- Thickness

- 30 mm, 50 mm, 75 mm, 100 mm (customizable)

- Features

- High strength-to-weight ratio, corrosion resistance, durable

- Purity

- PU foam core purity >95%

- Installation Type

- Interlocking/ tongue and groove system

- Load Capacity

- Varies as per thickness and design (refer datasheet)

- Product Type

- Polyurethane Sandwich Panel

- Main Material

- Polyurethane (PU) core with pre-painted galvanized steel sheets

- Surface Treatment

- Color coated / Pre-painted

- Size

- Standard width 1000 mm; length customizable as required

- Weight

- Approx. 8-12 kg/m (varies by thickness)

- Feature

- Lightweight, high thermal insulation, fire resistant, moisture proof

- Shape

- Rectangular panel

Polyurethane Sandwich Panel Trade Information

- Supply Ability

- 01 Piece Per Month

- Delivery Time

- 1-4 Week

About Polyurethane Sandwich Panel

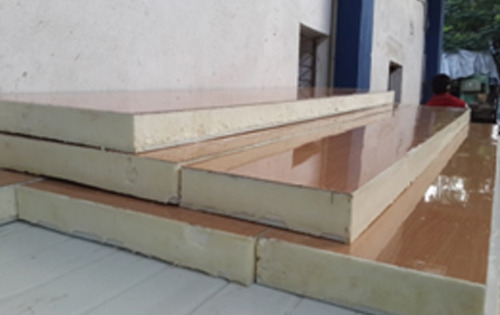

With an aim to become a leading entity in this field, we are engrossed in offering superior grade Polyurethane Sandwich Panel. At our sophisticated unit, the provided panel is fabricated under the stringent supervision of diligent professionals with the help of pioneering techniques. Known as the complete solution for all cladding needs, this panel protects the building from external environment. The offered Polyurethane Sandwich Panel is used for roofing of workshops, cold storage rooms etc.

Features:

- High thermal insulation

- Excellent impact resistance

- Fire proof

- Long life

Product Description:

We are engaged in manufacturing, exporting and supplying supreme quality array of Polyurethane Sandwich Panel. Our offered sandwich panel is strongly designed with quality proven basic material and the finest technology at our end. Given range of sandwich panel is accessible in various sizes and other linked specifications, to satisfy our valuable clients. This sandwich panel is broadly accredited among our customers for their durability. Patrons can take the complete assortment of sandwich panel from us at reasonable rates.

Features:

Features:

- Accurate dimension

- Low maintenance

- Compact design

- Length:Up to 6mtr

- Width:Up to 1.2mtr

- Thickness:25mm to 150mm

- Note:25mm to 40mm thickness available up to certain length

- Tongue and Groove with specially designed Cam Locks

- Density:40kg/m3

- GI Pre coated

- SS

- Bituminous Paper

- Aluminium Foil Paper

- Kraft Paper

- Ply

- FRP Sheets

- Aluminium etc

Precision Engineering for Diverse Applications

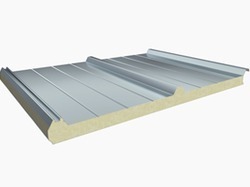

Designed using high-grade galvanized steel and a high-purity rigid polyurethane foam core, these sandwich panels deliver remarkable thermal insulation, soundproofing, and fire-resistance. Their tongue and groove interlocking system ensures quick, efficient installation, making them ideal for industrial buildings, warehouses, and cold storage facilities. Customizable thickness, color, and panel profiles meet varied architectural and functional requirements.

Strength Meets Sustainability

Combining high compressive strength and a durable color-coated exterior, these panels resist corrosion and are built to last over 20 years with proper maintenance. The CFC-free foam core and eco-friendly materials help minimize environmental footprint, positioning the panels as a sustainable solution for modern construction and export projects.

FAQs of Polyurethane Sandwich Panel:

Q: How are Polyurethane Sandwich Panels installed on site?

A: Polyurethane Sandwich Panels are installed using an interlocking tongue and groove system, or with cam-lock profiles if preferred. This design allows for straightforward alignment and secure joining, facilitating quick assembly for walls, roofs, and partitions.Q: What benefits do these panels offer for industrial and cold storage applications?

A: These panels provide high thermal insulation, moisture resistance, and sound dampening, enabling consistent internal temperatures and reduced energy costs. Their lightweight yet robust structure simplifies transportation and installation, while their fire resistance enhances overall safety.Q: Where can Polyurethane Sandwich Panels be used effectively?

A: They are suitable for use in industrial buildings, warehouses, cold rooms, commercial structures, and partitioning. Their customizable size and color options allow them to adapt to various architectural and operational requirements.Q: What is the process of customizing panel dimensions and appearance?

A: Customization involves specifying the required panel size, thickness (from 30 to 100 mm), color, and edge profile (straight or cam-lock). The panels are then manufactured to these specifications using advanced panel forming and laminating lines.Q: When should I consider using PU Sandwich Panels instead of traditional materials?

A: Choose PU Sandwich Panels when you require superior insulation, reduced installation time, long lifespan, and lightweight yet high-strength constructionespecially in environments demanding efficient thermal and moisture control, such as cold storage or industrial facilities.Q: What makes these panels environmentally friendly?

A: The panels use CFC-free, eco-friendly rigid PU foam and recyclable galvanized steel, minimizing environmental impact during manufacturing and use. Their durability also reduces material waste over their lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free